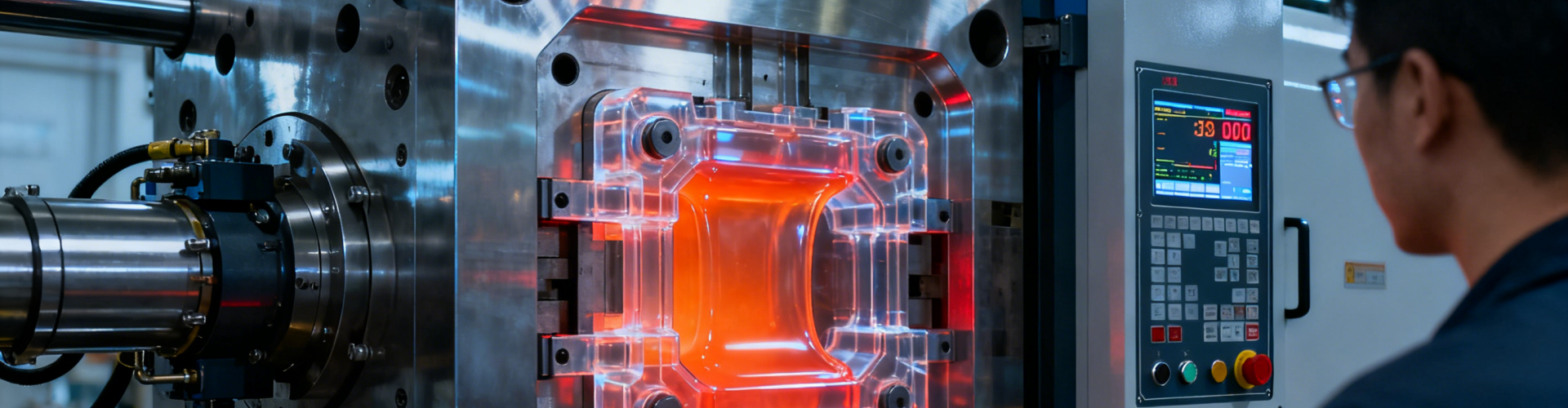

Overview: How Injection molding works?

The Basics Of Injection Molding Service

Injection molding is one of the most often-used manufacturing processes for creating plastic parts. Thanks to its high-precision, repeatability, and cost efficiency at scale, injection molding is used to make a variety of products and parts from the smallest medical insert up to large automotive & aerospace and defense parts. The injection molding process requires an injection molding machine, raw plastic material, and a machined mold. The raw plastic material is first melted in the injection unit and is then injected into the mold — most often machined from steel or aluminum — where it cools and solidifies into the final plastic part. The key steps in the injection molding process are clamping, injection, cooling, and ejection.

How Injection molding Works

The sequence of events during the injection mould of a plastic part is called the injection molding cycle. The key steps in the injection molding cycle are:

Clamping: The two sides of the mold are closed and clamped shut.

Injection: The material is fed into the machine and pushed towards the mold. While this is happening, the material is melted by heat and pressure. The plastic is then injected into the mold — this is called the “shot.”

Cooling: The plastic in the mold cools and solidifies into the shape of the part.

Ejection: After the part cools, it is ejected from the mold.

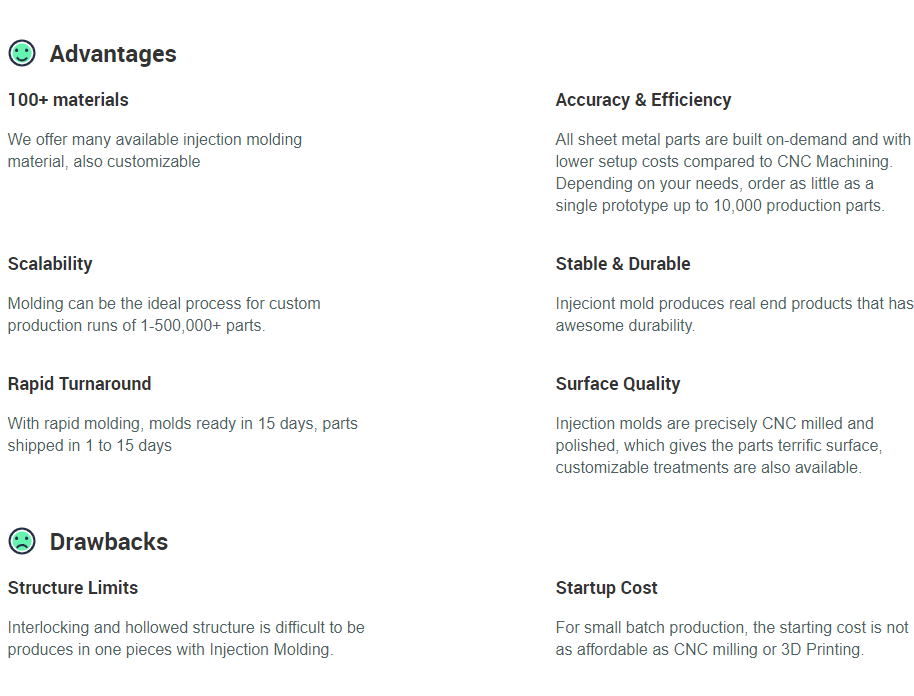

Features of Injection Molding Service

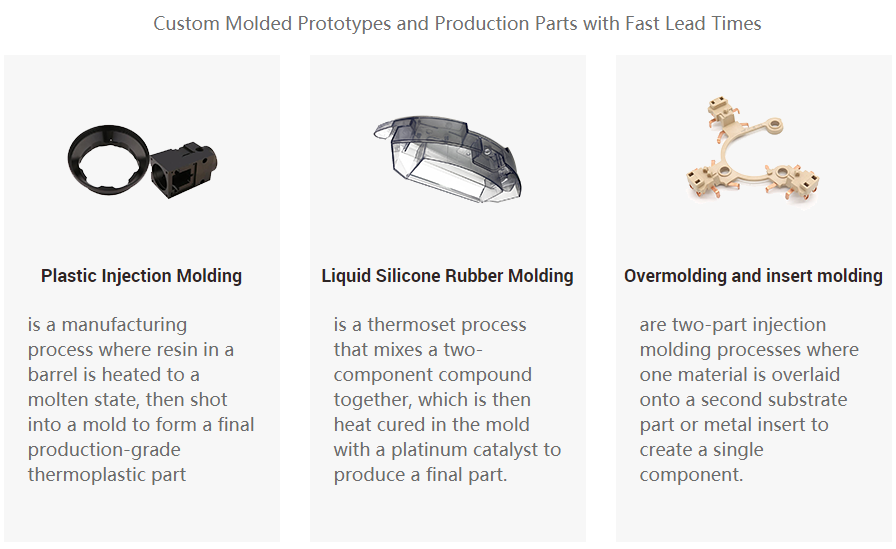

Injection Molding Processes

Injection Molding Materials

Rigid And Flexible Plastic Varieties,Rubber-Like Varieties

Hard Plastics

Flexible Plastics

Rubber-Like Varieties

Mixed plastic

CONTACT US TO GET INSTANT QUOTE